pipe

ERW

In the electric resistance welded (ERW) pipe industry, lean manufacturing principles are essential for maximizing efficiency, quality, and responsiveness. Lean methodologies are applied throughout the production process, from raw material procurement and pipe forming to welding and finishing. Continuous improvement initiatives encourage employees to identify and address inefficiencies, promoting a culture of ongoing innovation and operational excellence.

SEAMLESS

In the seamless pipe industry, lean manufacturing principles are pivotal in enhancing efficiency, quality, and responsiveness. By eliminating waste and optimizing workflows, manufacturers significantly reduce lead times and costs while maintaining the highest quality standards. Just-in-time inventory management ensures that materials are available exactly when needed, minimizing excess stock and storage costs.

SPIRAL

In the spiral pipe industry, lean manufacturing principles are crucial for enhancing efficiency, quality, and adaptability. By integrating lean manufacturing principles, the spiral pipe industry achieves optimal operational efficiency, cost-effectiveness, and the ability to consistently deliver high-quality pipes for a wide range of applications, including infrastructure and energy sectors.

UPVC

In the UPVC pipe industry, the implementation of lean manufacturing principles is essential for optimizing efficiency, quality, and customer satisfaction. Continuous improvement initiatives empower employees to identify inefficiencies and propose solutions, fostering a culture of innovation and ongoing enhancement. This approach allows the industry to quickly respond to changing market demands and customer requirements.

CPVC

In the CPVC pipe industry, the application of lean manufacturing principles is pivotal for enhancing efficiency, quality, and responsiveness. By focusing on waste elimination and process optimization, manufacturers can significantly reduce lead times and costs while maintaining high product standards. By integrating lean manufacturing principles, the CPVC pipe industry achieves superior operational efficiency, cost-effectiveness, and the ability to consistently deliver high-quality pipes.

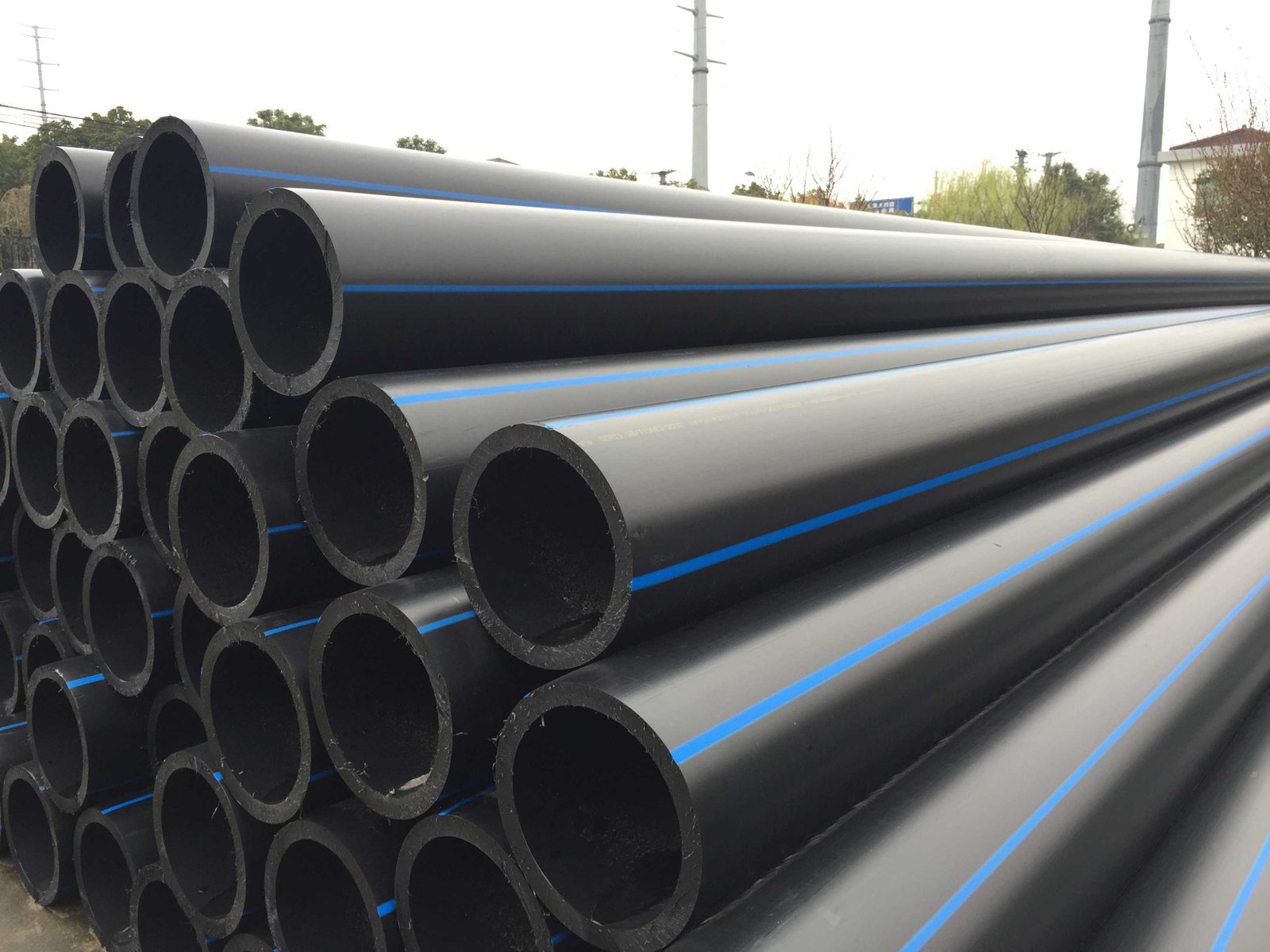

HDPE

In the HDPE pipe industry, lean manufacturing principles are essential for optimizing efficiency, quality, and sustainability. Continuous improvement initiatives empower employees to identify inefficiencies and implement solutions, fostering a culture of innovation and continuous enhancement. Rigorous quality control measures are implemented throughout the production process to ensure that each HDPE pipe meets stringent standards for durability, corrosion resistance, and dimensional accuracy.