Automotive

ALLOY WHEELS

Alloy wheels, guided by the principles of lean manufacturing, operate at the forefront of efficiency and quality in the manufacturing of automotive components. Strict quality control measures are implemented to maintain the highest standards and ensure that each alloy wheel meets the strict requirements. Using lean techniques, we helped our clients in the alloy wheel business achieve the following outcomes:

- Increased availability by 5%

- Increased production by 10%

- Reduced wastage by 16%

- Reduced changeover time by 20%

- Reduced FG inventory by 18%

- Reduced stored inventory by 15%

- Reduced FG dead stock by 69%

CHUCKS MANUFACTURES

Chuck’s manufacturing facility uses lean manufacturing principles to streamline manufacturing processes and maximize efficiency. Through continuous improvement initiatives, the company minimizes inventory levels, maintains high-quality standards, and increases flexibility to adapt to rapidly changing market demands. By adopting Lean methods, Chuck’s achieves not only operational excellence but also ensures customer satisfaction through timely delivery of durable and reliable products.

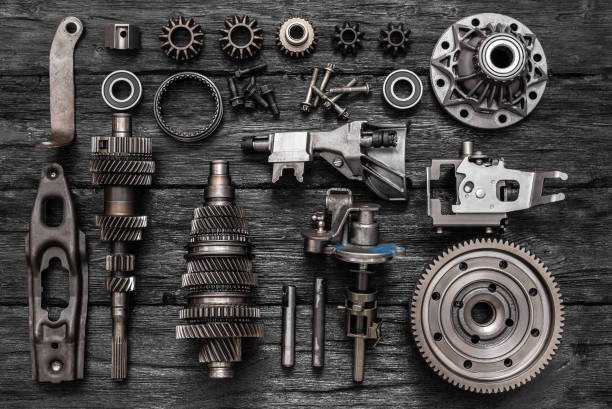

AUTO SPARE PARTS

In the auto spare parts industry, by eliminating waste, optimizing workflows, and fostering a culture of continuous improvement, we guide our spare parts manufacturers to streamline their processes to meet the dynamic demands of the automotive market, minimizing inventory costs while maintaining high levels of availability.

- Reduced boiler fuel cost by 60.29%

- Increased boiler condensing water efficiency by 62%

- Reduced rectifier power cost by 10%

- Optimized manpower in operations by 2%

- Overall saving of Rs 3.36Cr+

AGRICULTURE AUTO PARTS

An agricultural grain manufacturer uses lean manufacturing principles to streamline its manufacturing processes and improve overall efficiency. Every production step, from the acquisition of raw materials to the assembly of the cutting blade, is carefully optimised to avoid waste and minimise costs. Using Lean principles, the manufacturer not only achieves maximum performance but also ensures a consistent supply of high-quality agriculture blades to meet the needs of farmers and agricultural equipment manufacturers.